Tesla has been sourcing cathode material from two Chinese electric vehicle battery makers for its production of 4680 batteries (high energy density cells 46 millimeters in diameter and Dear Utol (2025): Week 7 Highlights 4080 mm in length) in Texas since the second half of 2023. The deals are expected to continue until at least the third quarter of this year. Rather than purchasing battery cells directly, the US automaker procured positive electrode coils – raw electrodes processed into rollers that account for 35% of the cost of a battery cell – people with knowledge of the matter told media outlet LatePost. The move is expected to help Tesla ramp up production of the cost-efficient cylindrical battery cells, the report added. In an article by Reuters last March, China’s Ningbo Ronbay New Energy and Suzhou Dongshan Precision Manufacturing were mentioned as two companies Tesla had turned to to help lower battery materials costs. Battery-related production issues are partly responsible for delays in launching Tesla’s futuristic Cybertruck. [LatePost, in Chinese]

Related Articles

2025-06-26 00:58

2429 views

The Trash of the System

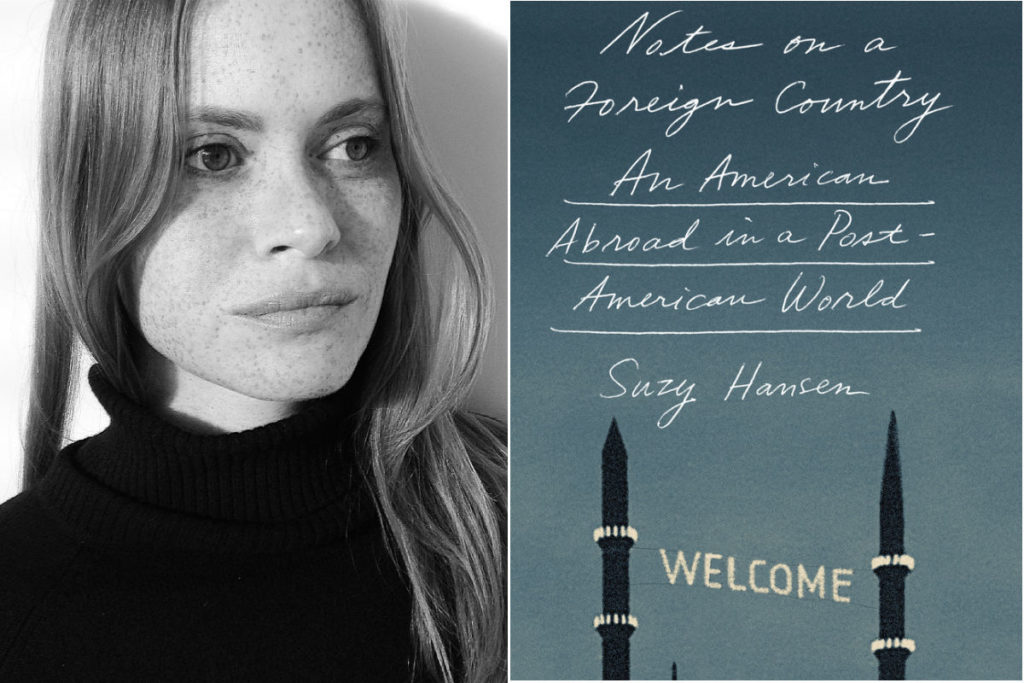

Dan Duray ,November 20, 2017 The Trash of

Read More

2025-06-26 00:44

2951 views

Jewish Comedy Is Serious Business

Jewish Comedy Is Serious BusinessBy Jeremy DauberOctober 13, 2017HumorFrom Nize Babyby Milt Gross (1

Read More

2025-06-26 00:28

1071 views

Staff Picks: Witch

Staff Picks: Witch-Hop, Typingpool, and SalkisBy The Paris ReviewOctober 13, 2017This Week’s Reading

Read More